UTM/DTM (Ultrasonic / Digital Thickness Measurement)

Why take this course?

Course Title: Mastering UTM/DTM: Piping/Welding Inspection in High-Stake Environments 🚀

Headline: Elevate Your Expertise in Refinery, Power Plants, & Offshore Energy Solutions with Advanced NDT Techniques! 🏭✨

Course Overview:

Welcome to the comprehensive UTM/DTM (Ultrasonic Thickness Measurement/Digital Thickness Measurement) course tailored specifically for working professionals in the Oil & Gas Industry. This course is designed to empower Mechanical Engineers, QA/QC Engineers, Welding Engineers, and NDT (Non-Destructive Testing) Engineers with a deep understanding of Penetrant Testing (PT) techniques, including DP-Dye Penetrant and LPT-Liquid Penetrant methods.

What You'll Learn:

Foundational Knowledge:

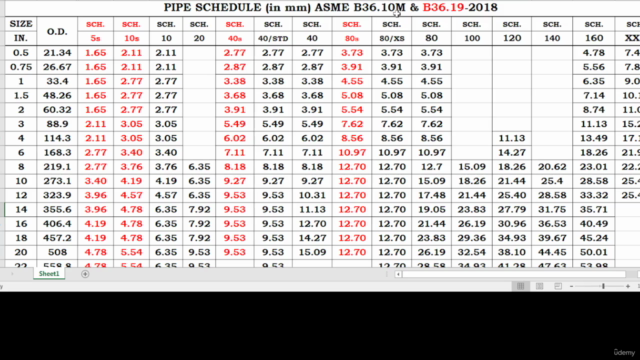

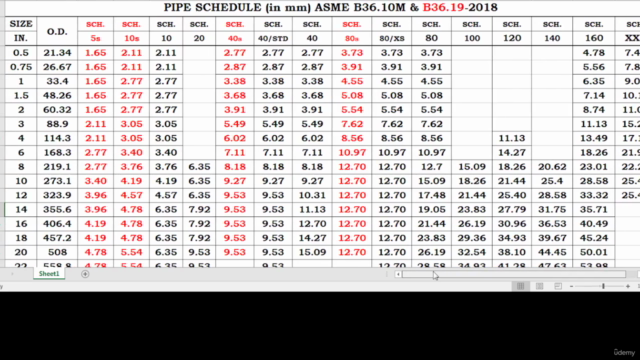

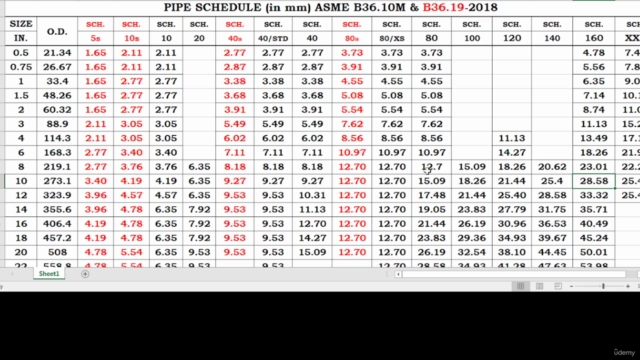

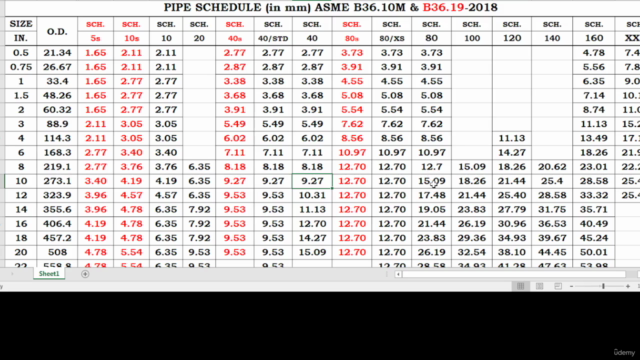

- Mastery of codes, specifications, procedures, formats, ITP, QAP, Isometric Drawings, P&ID, PFD, GA, Drawings, Audit Plans, and Training Plans.

- Expertise in NDT Reports, Loop Files, and Test Packs.

Hands-On Skills:

- Warehouse Management, Fit-Up, Welding & Fabrication, Erection, Blasting, Painting, Hydrotesting, and Punch Point Analysis.

- Proficiency in Cardboard Blasting, Insulation, Oxygen Service Cleanliness, Box-up, Hand Over, Preservation, Shutdown, Maintenance, Dossier Management, Corrosion Prevention, Continuous Improvement Processes, Soft Skill Development, and Behavior Change.

Safety & Compliance:

- Enhanced understanding of safety, toolbox talks, and housekeeping in high-risk environments like offshore platforms and nuclear plants.

Course Highlights:

- Expertise Development: Become an expert in the Oil & Gas Industry, mastering refineries, petrochemical complexes, cross-country pipelines, well pads, and offshore platforms.

- Diverse NDT Techniques: Dive into Dye Penetrant Testing, Magnetic Particle Testing, Radiography Testing, Ultrasonic Testing, Visual Testing, Radiography Film Review, and more advanced techniques like Phased Array Ultrasonic Testing and Time of Flight Diffraction (ToFD) Ultrasonic Testing.

- UTM/DTM Mastery: Understand the critical role of UTM/DTM in monitoring corrosion in refineries, power plants, vessels, tanks, and offshore platforms.

Why Take This Course? 🎓

- Professional Growth: Elevate your interview skills and confidence as you delve into the world of NDT and piping inspection.

- Safety & Reliability: Learn to ensure the integrity, safety, and efficiency of pipelines and welding discontinuities in some of the most demanding environments.

- Maintenance Excellence: Master the dossier process for effective maintenance planning, execution, and reporting to prevent corrosion and enhance longevity.

- Networking Opportunities: Connect with peers and industry experts who share your passion for NDT and piping inspection.

Who Should Enroll?

This course is perfect for:

- Mechanical Engineers seeking to specialize in NDT within the Oil & Gas Industry.

- QA/QC Engineers aiming to improve their technical knowledge and skills.

- Welding Engineers looking to enhance their understanding of discontinuity inspection.

- NDT Engineers, Technicians, and Inspectors who want to upgrade their expertise in advanced NDT techniques.

Course Format:

- Engaging video content and interactive sessions.

- Hands-on practice with real-world scenarios.

- Case studies from industry leaders in piping inspection and NDT.

- Access to a dedicated support community for peer learning.

Join us on this journey to become a seasoned expert in the field of Ultrasonic Thickness Measurement and Digital Thickness Measurement, ensuring the highest standards of safety, efficiency, and reliability in the Oil & Gas Industry. 🛢️💧🚀

Course Gallery

Loading charts...