Loop File, LHS, Punch Point, Pressure Test, Box up, Handover

Why take this course?

Course Headline: Mastering Piping & Welding in High-Stake Environments

🛠️ About the Course: This comprehensive online course is tailored for working professionals in the Oil & Gas Industry, particularly Mechanical Engineers, QA/QC Engineers, Welding Engineers, and NDT Engineers. It is designed to enhance your skill set and confidence during interviews, shutdowns, maintenance, production, and beyond.

🚀 What You'll Learn:

- In-Depth Knowledge: Gain a thorough understanding of codes, specifications, procedures, formats, ITPs, QAPs, Isometric Drawings, P&ID D diagrams, PFDs, GA drawings, Audit Plans, Training Plans, and NDT Reports.

- Practical Skills: Master Warehouse Management, Fit Up, Welding, Fabrication, Erection, NDT, Blasting, Painting, Hydro Testing, Punch Point Clearance, Cardboard Blasting, Insulation, Oxygen Service Cleanliness, Box-up, and Handover processes.

- Soft Skills & Safety: Develop essential soft skills, understand behavior change for safety, conduct Toolbox Talks, ensure House Keeping, and learn the importance of Corrosion Prevention and continuous improvement processes.

🔧 Hands-On Learning: This course will equip you with expert knowledge in various aspects of piping and welding, including:

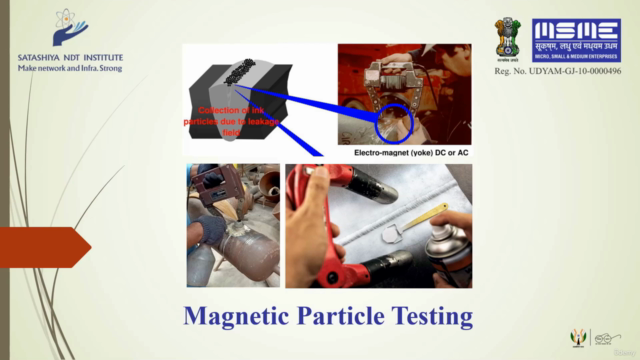

- NDT Techniques: Dive into Dye Penetrant Testing, Magnetic Particle Testing, Radiography Testing, Ultrasonic Testing, Visual Testing, and more.

- Advanced Testing Methods: Learn about Radiography Film Review, Digital Thickness Gauging, and master cutting-edge technologies like Phased Array Ultrasonic Testing and Time of Flight Diffraction Ultrasonic Testing.

🏭 Real-World Applications: Become an expert in maintaining the integrity of pipelines, refineries, petrochemical complexes, cross-country pipelines, well pads, and offshore platforms. Understand the nuances of Shutdown and Maintenance Dossiers and ensure the highest standards of safety and quality assurance.

🎓 Course Highlights:

- ASME Code Familiarity: Learn the intricacies of the ASME Code and its relevance to piping systems.

- Welding Process Mastery: Understand various welding processes and their applications in different scenarios.

- Comprehensive NDT & Blast Knowledge: Get a detailed grasp of non-destructive testing, blast and painting procedures, Corrosion Rate Calculation, and Hydro Testing.

- Loop File & Punch Point Clearance: Learn how to effectively manage Loop Files and perform Punch Point Clearances to ensure operational efficiency and safety.

👥 Who Should Take This Course? This course is ideal for:

- Mechanical Engineers

- QA/QC Engineers

- Welding Engineers

- NDT Engineers

- Mechanical Technicians

- Inspectors & Surveyors

- Safety Officers

- Anyone looking to advance their career in the Oil & Gas Industry.

📅 Why Enroll Now? By enrolling in this course, you will not only enhance your technical knowledge but also develop critical soft skills that are essential for a successful career in the demanding environment of construction and maintenance in refineries, power plants, pipelines, offshore, nuclear plants, and energy sectors.

🔍 Instructor Expertise: Learn from Mansukh Satashiy, an industry veteran with extensive experience in Penetrant Testing (DP/LPT) and other NDT methodologies. His expertise will guide you through the complexities of piping systems, ensuring your success in the field.

🛠️ Course Modules:

-

Fundamentals of Piping & Welding:

- Understanding the ASME Code and its relevance to your work.

- Exploring different welding processes and their applications.

-

Non-Destructive Testing (NDT):

- Mastering Dye Penetrant and Magnetic Particle testing techniques.

- Learning advanced testing methods like Radiography, Ultrasonic, Visual, and more.

-

Practical Skills & Procedures:

- Executing Fit Up, Welding, Fabrication, Erection with precision.

- Handling Blasting, Painting, Hydro Testing, and Punch Point Clearance.

-

Maintenance & Safety Excellence:

- Implementing safety measures and conducting Toolbox Talks.

- Ensuring House Keeping and Corrosion Prevention in piping systems.

-

Documentation & Reporting:

- Creating Loop Files, Test Packs, and NDT Reports effectively.

- Understanding the importance of Audit Plans, Training Plans, and continuous improvement processes.

-

Real-World Applications:

- Applying your knowledge to Shutdown and Maintenance Dossiers in various industries.

- Maintaining the integrity of critical infrastructure like refineries, power plants, pipelines, offshore platforms, and nuclear plants.

🎓 Enroll Today to Propel Your Career Forward!

By mastering this critical skill set, you will be well-equipped to tackle the demands of your field and advance your career in the dynamic world of piping and welding within the Oil & Gas Industry. Don't miss out on the opportunity to become an expert and a leader in your domain. 💼🚀

Course Gallery

Loading charts...