CSWIP 3.1, BGAS, NACE, API AWS, ASME ASTM ASNT Code Training

Why take this course?

🛠️ Mastering ASME Piping and Welding in High-Stake Environments

Course Headline:

ASME Piping/Welding in Construction and Maintenance for Refinery, Power Plants, Pipeline, Offshore & Nuclear Energy Industries

Course Description:

Are you a professional working within the Oil & Gas sector, with a focus on Mechanical Engineering, QA/QC, Welding, or NDT? Or are you aiming to enter this dynamic field? Our comprehensive online course, led by the esteemed Mansukh Satashiy, is designed to elevate your expertise in Pipeline Inspection and Maintenance. This course will delve into the intricacies of the ASME (American Society of Mechanical Engineers) codes, specifically CSWIP 3.1, BGAS, NACE, API AWS, and ASNT standards.

Key Learning Areas:

-

Knowledge Enhancement: Gain a deep understanding of code specifications, procedures, formats, ITP (Inspection Test Plans), QAP (Quality Assurance Plans), Isometric Drawings, P&IDs (Piping & Instrumentation Diagrams), PFDs (Process Flow Diagrams), GA (General Arrangement), Drawings, Audit Plans, Training Plans, and the preparation of NDT Reports, Loop Files, Test Packs, and Test Circuits.

-

Hands-On Skills: Learn about Warehouse Management, Fit-up, Welding, Fabrication, Erection, NDT techniques (including Dye Penetrant, Magnetic Particle, Radiography, Ultrasonic testing, and Visual testing), Blasting and Painting, Hydro test, Punch Point Identification, Cardboard blasting, Insulation, Oxygen Service Cleanliness, Box-up, Hand Over, Preservation, and safety measures like House Keeping.

-

Maintenance Excellence: Master the art of Shutdown and Maintenance procedures, Corrosion Prevention, Continuous Improvement Processes, Soft Skill Development, Behavior Change, Safety Protocols (Tool Box Talks), and Effective Communication.

-

Expertise in Oil & Gas Sectors: Become an expert in critical areas such as refineries, petrochemical complexes, cross-country pipelines, well pads, and offshore platforms.

-

Advanced NDT Techniques: Get hands-on experience with advanced testing methods like Digital Thickness Test, Phased Array Ultrasonic Testing, and Time of Flight Diffraction Ultrasonic Testing. Learn Radiography Film Review to ensure the integrity of welds and other critical components.

What You Will Achieve:

-

Inspection Mastery: Acquire the essential knowledge required for Inspection Engineers, including an understanding of ASME Code, Welding Processes, Piping Systems, NDT Techniques, Blasting and Painting, Corrosion Rate Calculation, Hydro Testing, Pneumatic Testing, and Line History Sheets.

-

Loop File & Punch Point Clearance: Learn the necessary steps for Loop File Clearance, Punch Point Clearance, Box-up, Cardboard Blasting, and Handover procedures to ensure a seamless transition during maintenance or shutdowns.

-

Confidence and Skill Enhancement: Not only will you gain technical knowledge but also improve your interview skills and build confidence in your professional capabilities.

🎓 Who Should Attend?

This course is ideal for:

- Mechanical Engineers

- Working Professionals in the Oil & Gas Industry

- Welding Engineers

- NDT Engineers

- Execution, QA/QC Engineers

- Maintenance Personnel

- Anyone aiming to enhance their skills and knowledge in ASME piping and welding standards and NDT techniques.

Join us to become a specialist in the field of Pipeline Inspection and Maintenance, and take your career to new heights within the high-stakes environments of Refinery, Power plants, Cross Country Pipelines, Offshore Platforms, and Nuclear plants. 🚀

Enroll now and transform your expertise with our expert-led course on ASME Piping/Welding in Construction and Maintenance! 🛠️🏭✨

Course Gallery

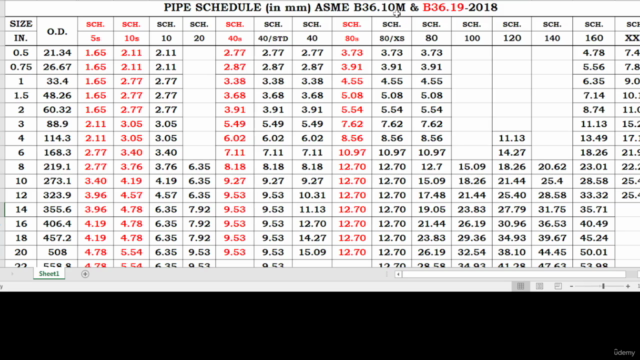

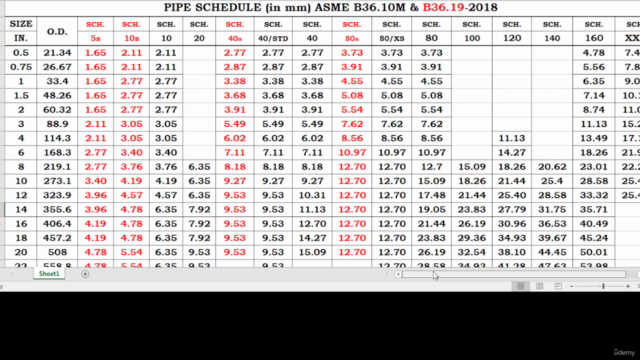

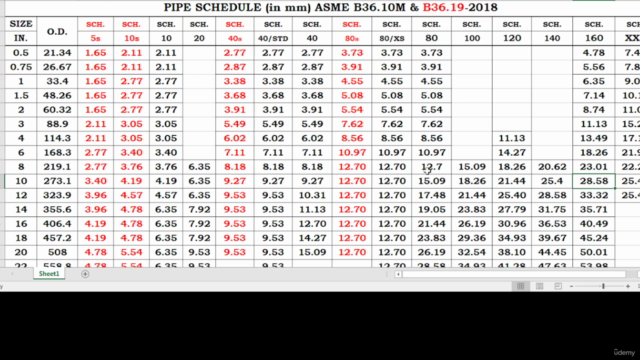

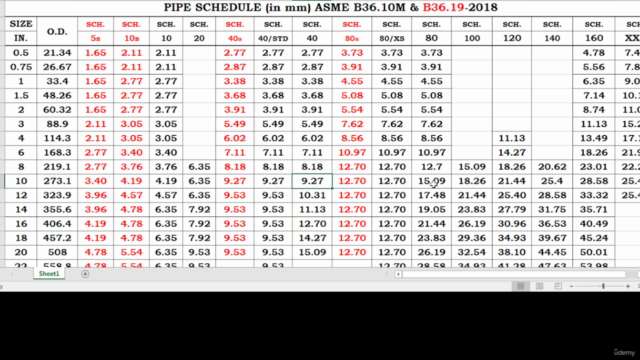

Loading charts...